FormFab: Towards Shape Exploration in Interactive Fabrication

Stefanie Mueller, Anna Seufert, Huaishu Peng, Robert Kovacs, Kevin Reuss, François Guimbretière, Patrick Baudisch

In Proc. TEI'19. Full Paper

paper: PDF

ACM Digital Library

FormFab is an interactive fabrication system that can change a workpiece’s shape continuously while the user is interacting. This enables users to explore different sizes of a shape with a single interaction rather than in multiple turns. We accomplish this using a process called formative fabrication, which rather than adding or subtracting, reshapes the existing material. In our system, users interactively control a pneumatic air pump that applies either pressure or vacuum to a compliant thermoplastic sheet, thereby pushing the material outwards or pulling it inwards.

![]()

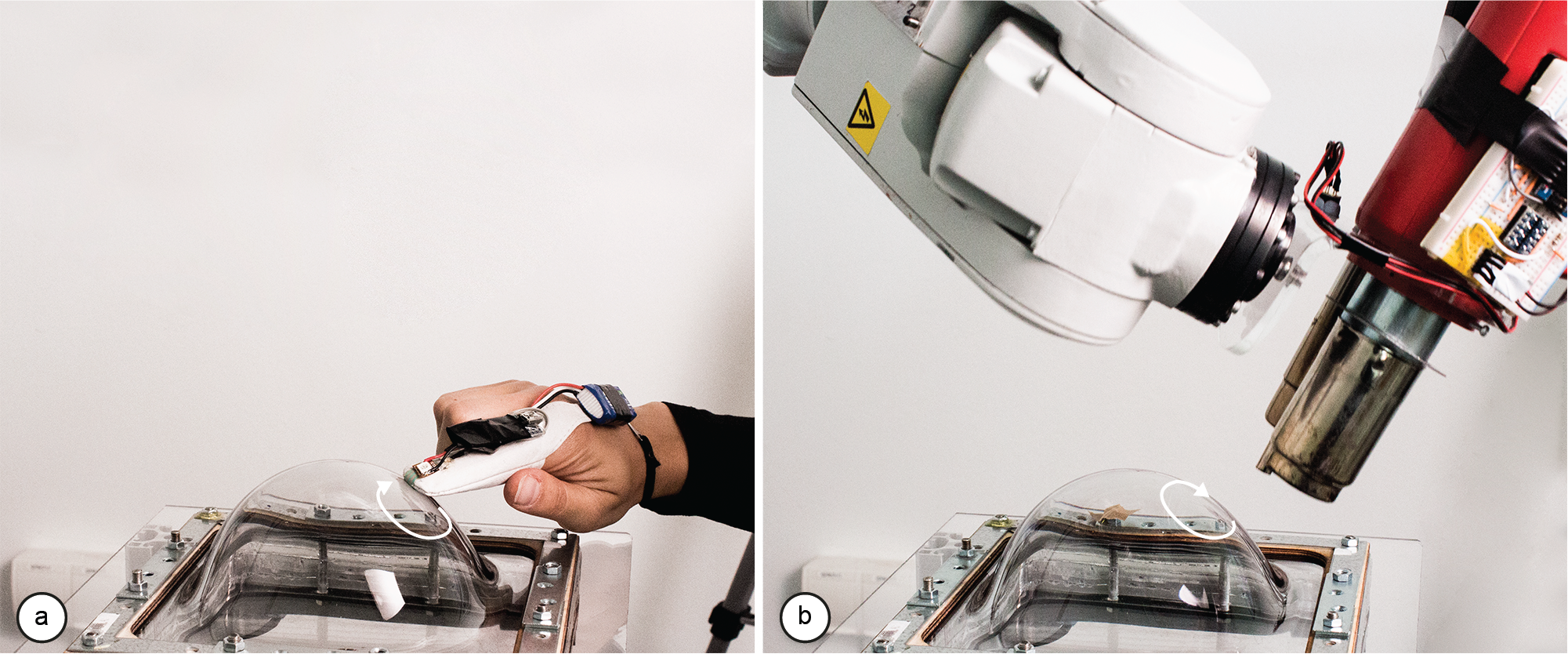

To achieve this, FormFab does not add or subtract material but instead reshapes it (formativefabrication). A heat gun attached to a robotic arm warms up a thermoplastic sheet until it becomes compliant; users then control a pneumatic system that applies either pressure or vacuum thereby pushing the material outwards or pulling it inwards.

![]()

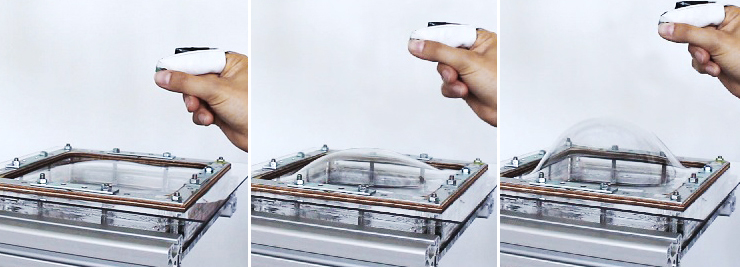

First, users draw an outline of the area they want to reshape using their index finger. When the user removes the finger, the path is beautified by our software. The robotic arm then warms up the areausing a heat gun.

After the material has reached its compliance point, the robotic arm moves out of the way. The user can then perform a pinch gesture, which activates the pneumatic system. If the user’s hand moves away from the workpiece, the pneumatic system increases the air pressure and the compliant area inflates.

![]()

To track the user interaction, FormFab users wear a motion capture marker and a pressure sensor on their index finger. The marker is detected by a motion capture system (OptiTrack) and used to determine wherethe user is interacting on the workpiece. In addition, the pressure sensor is used to determine the beginning and end of the interaction.

![]()

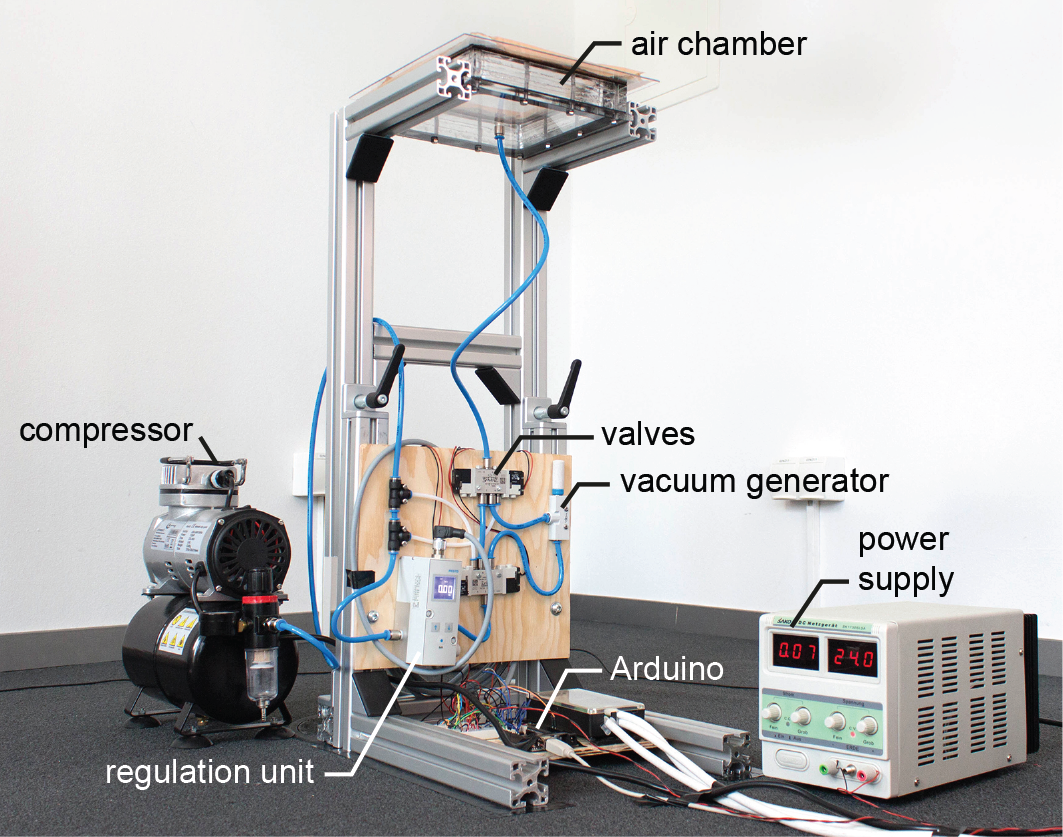

To reshape the workpiece, FormFab uses a compressed air. The air is guided through different valves, depending on whether pressure or vacuum should be applied

to the workpiece.

![]()

More Information:

https://hpi.de//baudisch/projects/formfab.html

https://hcie.csail.mit.edu/research/formfab/formfab.html

Stefanie Mueller, Anna Seufert, Huaishu Peng, Robert Kovacs, Kevin Reuss, François Guimbretière, Patrick Baudisch

In Proc. TEI'19. Full Paper

paper: PDF

ACM Digital Library

FormFab is an interactive fabrication system that can change a workpiece’s shape continuously while the user is interacting. This enables users to explore different sizes of a shape with a single interaction rather than in multiple turns. We accomplish this using a process called formative fabrication, which rather than adding or subtracting, reshapes the existing material. In our system, users interactively control a pneumatic air pump that applies either pressure or vacuum to a compliant thermoplastic sheet, thereby pushing the material outwards or pulling it inwards.

To achieve this, FormFab does not add or subtract material but instead reshapes it (formativefabrication). A heat gun attached to a robotic arm warms up a thermoplastic sheet until it becomes compliant; users then control a pneumatic system that applies either pressure or vacuum thereby pushing the material outwards or pulling it inwards.

First, users draw an outline of the area they want to reshape using their index finger. When the user removes the finger, the path is beautified by our software. The robotic arm then warms up the areausing a heat gun.

After the material has reached its compliance point, the robotic arm moves out of the way. The user can then perform a pinch gesture, which activates the pneumatic system. If the user’s hand moves away from the workpiece, the pneumatic system increases the air pressure and the compliant area inflates.

To track the user interaction, FormFab users wear a motion capture marker and a pressure sensor on their index finger. The marker is detected by a motion capture system (OptiTrack) and used to determine wherethe user is interacting on the workpiece. In addition, the pressure sensor is used to determine the beginning and end of the interaction.

To reshape the workpiece, FormFab uses a compressed air. The air is guided through different valves, depending on whether pressure or vacuum should be applied

to the workpiece.

Conclusion

In this paper, we showed a first prototype implementation of an interactive fabrication system that provides the user with physical feedback while the user is interacting. While the first step of selecting the area still followed the turntaking model, the second step of defining the size of the shape provided the user with simultaneous physical feedback, thereby bringing the principles of direct manipulation to the editing of physical objects.More Information:

https://hpi.de//baudisch/projects/formfab.html

https://hcie.csail.mit.edu/research/formfab/formfab.html